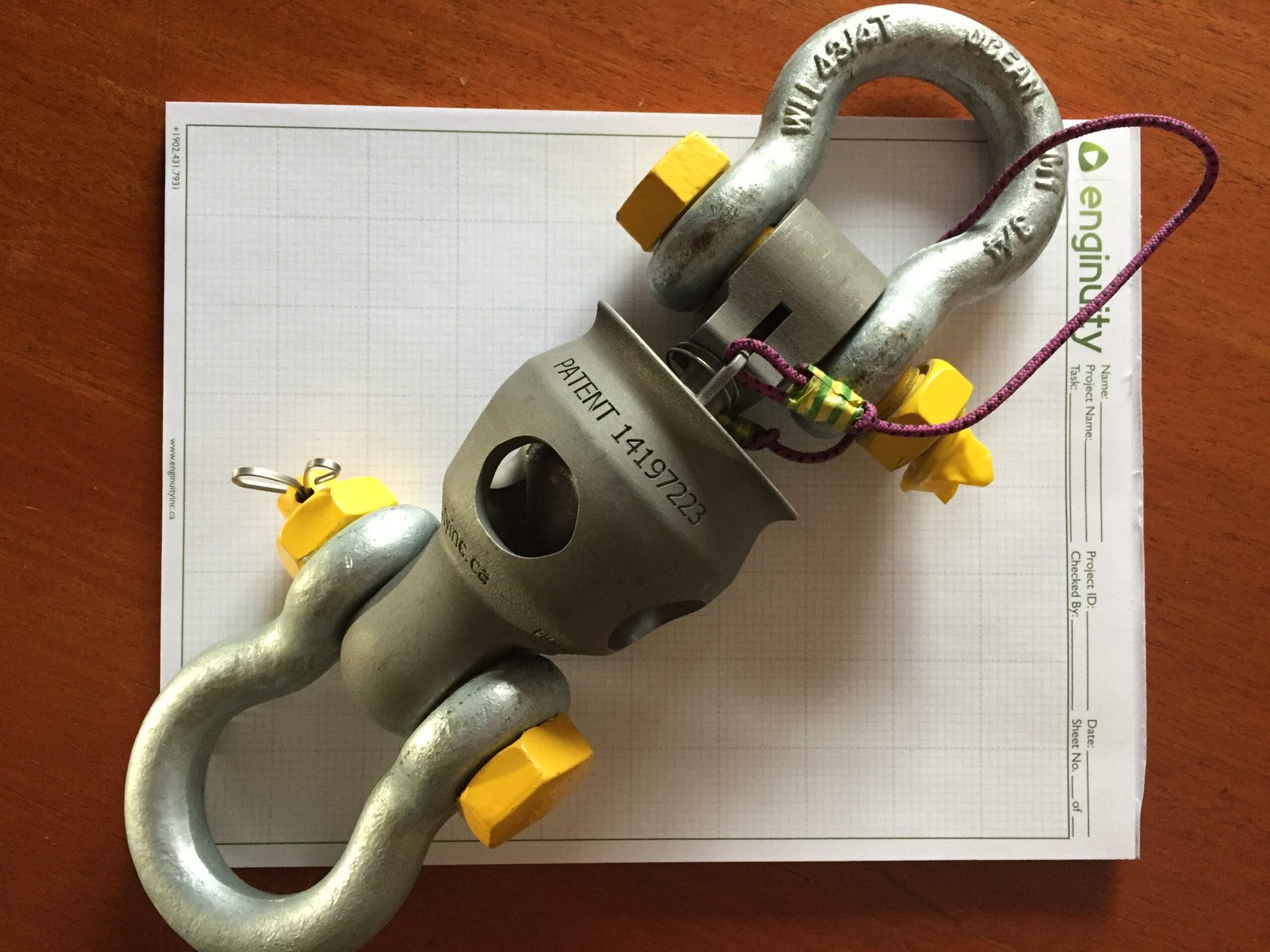

SEA-Stab™

SEA-Stab™ is a rapidly deployed, reusable, high-load mooring connector designed for the most challenging marine environments. It features high tolerance to approach angles and instant grab technology, allowing full load to be applied within seconds of connection.

SEA-Stab™ – The obvious choice for fast and long-term mooring

Whether you’re installing wind turbines, a new spread for an offloading system or replacing a

line on an FPSO, SEA-Stab™ from Enginuity offers simple, cost-effective and rapid connection.

Designed to be stronger than any equivalent sized chain, with a fully scalable design allowing for

working loads up to 30,000kN.

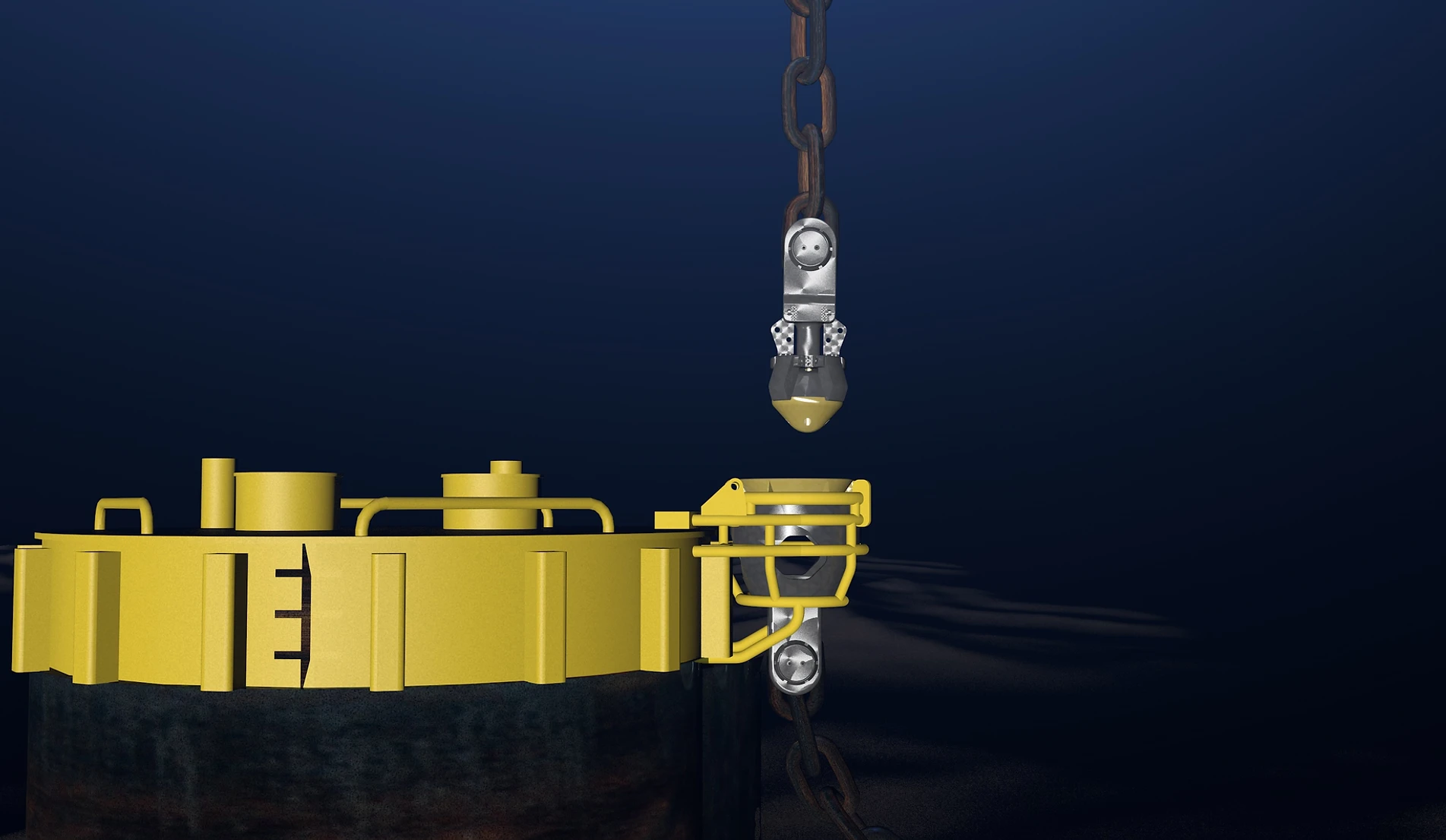

Floating wind turbine and wave energy mooring

Subsea asset deployment and retrieval

Buoy and 'Aids Navigation' management

Underwater arches and Subsea buoyancy

Stable mooring in harsh environment

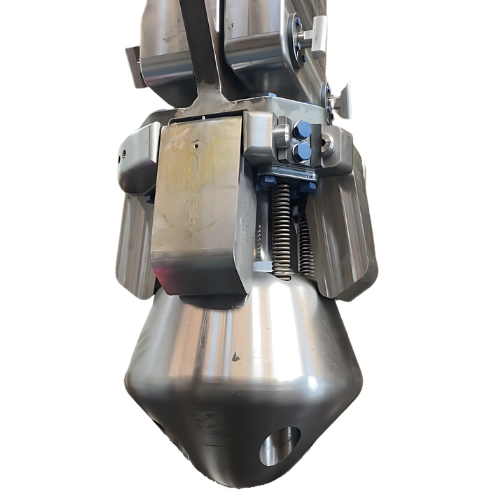

Permanent Mooring Connection Made Simple

A new subsea mooring connector that’s lighter, simpler, stronger and more cost effective than traditional ‘ball and taper’ technology. Our SEA-Stab™ outperforms traditional permanent or reconnectable technologies.

- Zero deformation at full chain MBL, ensuring connector remains truly reconnectable

- Cost effective design reduces capital cost

- Self-centers during deployment with wide approach angles, reducing installation costs

- Fully inspectable during installation and throughout life, ensuring ‘fitness for purpose’

- Only 5 Moving parts with no dissimilar materials reducing corrosion risk

- Configurable coupling reduces need for additional components during hook-up

SEA-Stab™ in Action

Frequently Asked Questions

What is the safety factor for the assembly?

Mooring connectors are typically rated based on their Minimum Break Load (MBL), which is the amount of weight required to begin yielding the material. When specifying the SEA-Stab, calculations are made to ensure that the intended mooring conditions are understood, and the connector is rated to withstand the highest loads likely to occur during the mooring period. A safety factor is always applied to this upper load, taking into account material age and fatigue.

Can the connector release under load?

In its standard configuration and by design, the SEA-Stab™ connector cannot release under load. All load must be fully removed before the connector can be released. This ensures secure and reliable operation under all conditions.

Are the connectors proof loaded?

All SEA-Stab™ units are proof-loaded to 125% of their SWL rating before leaving the factory. Load test certificates are available for an additional fee.

Is there a secondary means of locking the assembly closed?

All SEA-Stab™ units include locking screws that allow the user to lock the assembly closed for long-term connection. Larger connectors may have more complex secondary locking mechanisms, including ROV locks, hydraulic disconnection, etc. Please contact us to discuss your specific use case.

What maintenance is required?

SEA-Stab™ units are typically coated with a two-part marine epoxy prior to installation. In-service inspection is recommended as part of a broader mooring integrity plan.