SEA-Lift™

As ocean technologies evolve, the challenges of ocean asset management persist. Traditional methods of Launch and Retrieval (L&R) are costly, time-intensive, and hazardous for both military and commercial operations.

SEA-Lift™ is the heavy duty release and retrieval system designed for challenging marine environments. It provides a safe, secure, and reusable offshore connector designed for harsh environments.

SEA-Lift™ – Safety, Security & Speed for Offshore Lifting

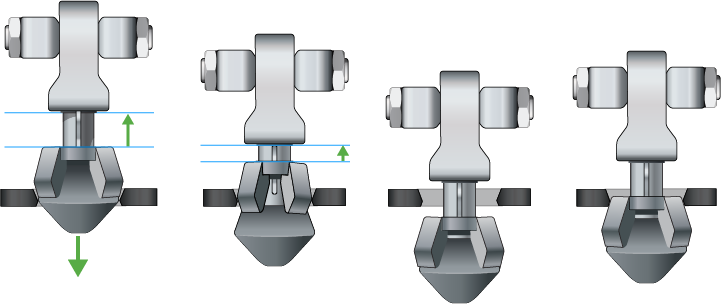

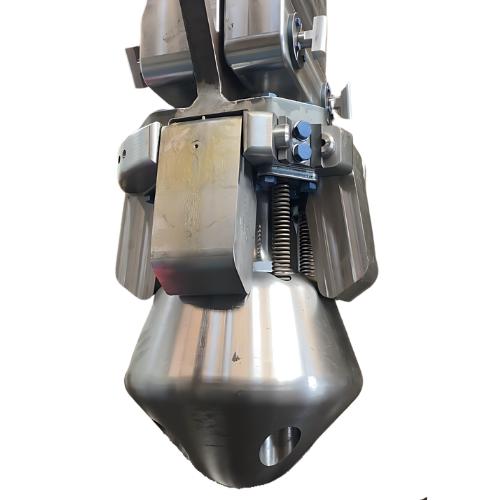

SEA-Lift™ is engineered to surpass traditional lifting technology, offering a design that is stronger than any equivalent-sized chain and fully scalable for working loads up to 100 te WLL. The optional deployment cone enables a high approach angle and self-centers during connection, ensuring efficient and accurate alignment.

The system features redundant secondary locking mechanisms, with options for remote release, providing unparalleled security even in the most harsh environments. This instant connection reduces costs and enables downline recovery for retrieving lost assets in challenging environments.

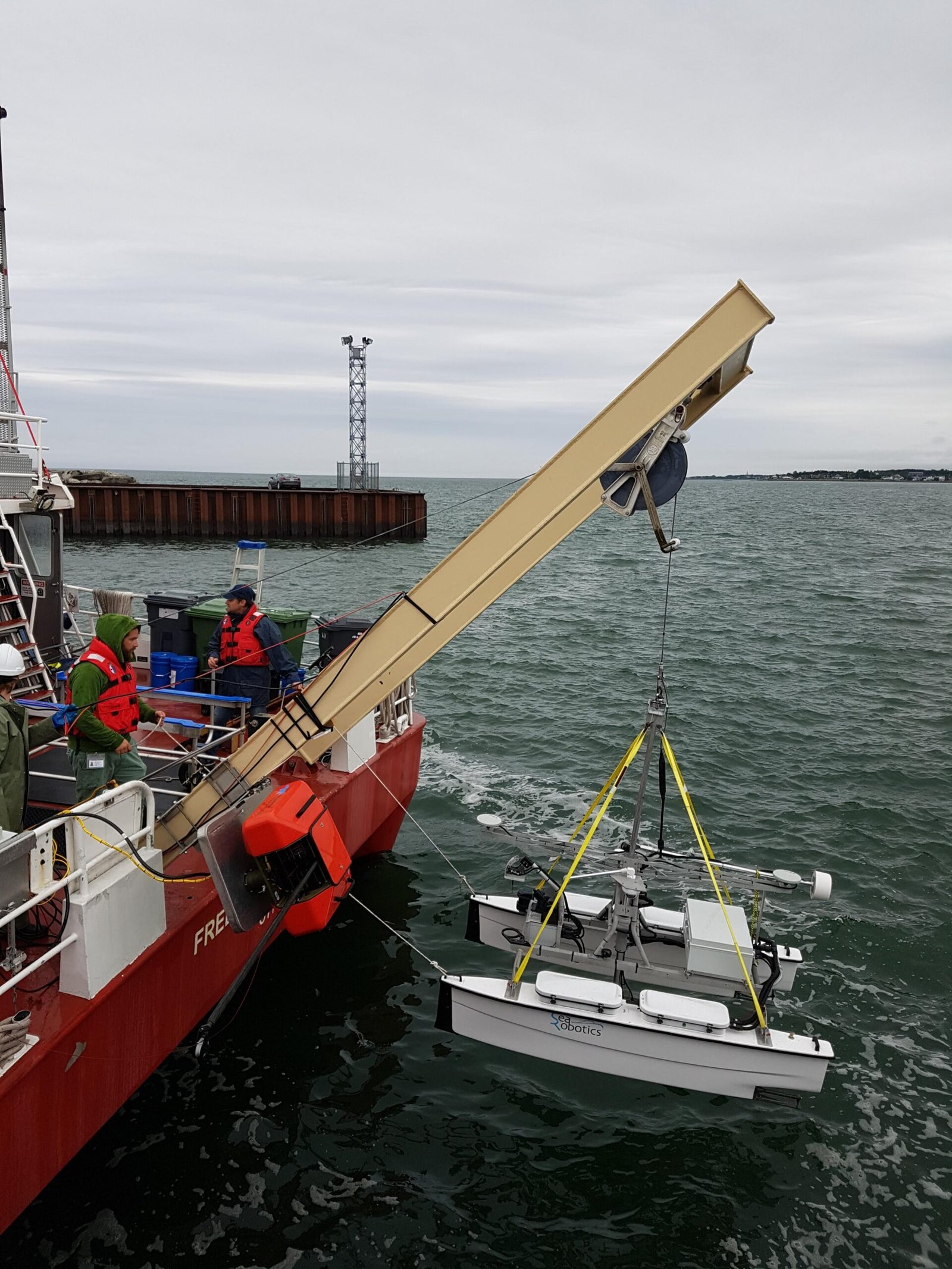

AUV Handling and Recovery

Offshore cargo loading and unloading

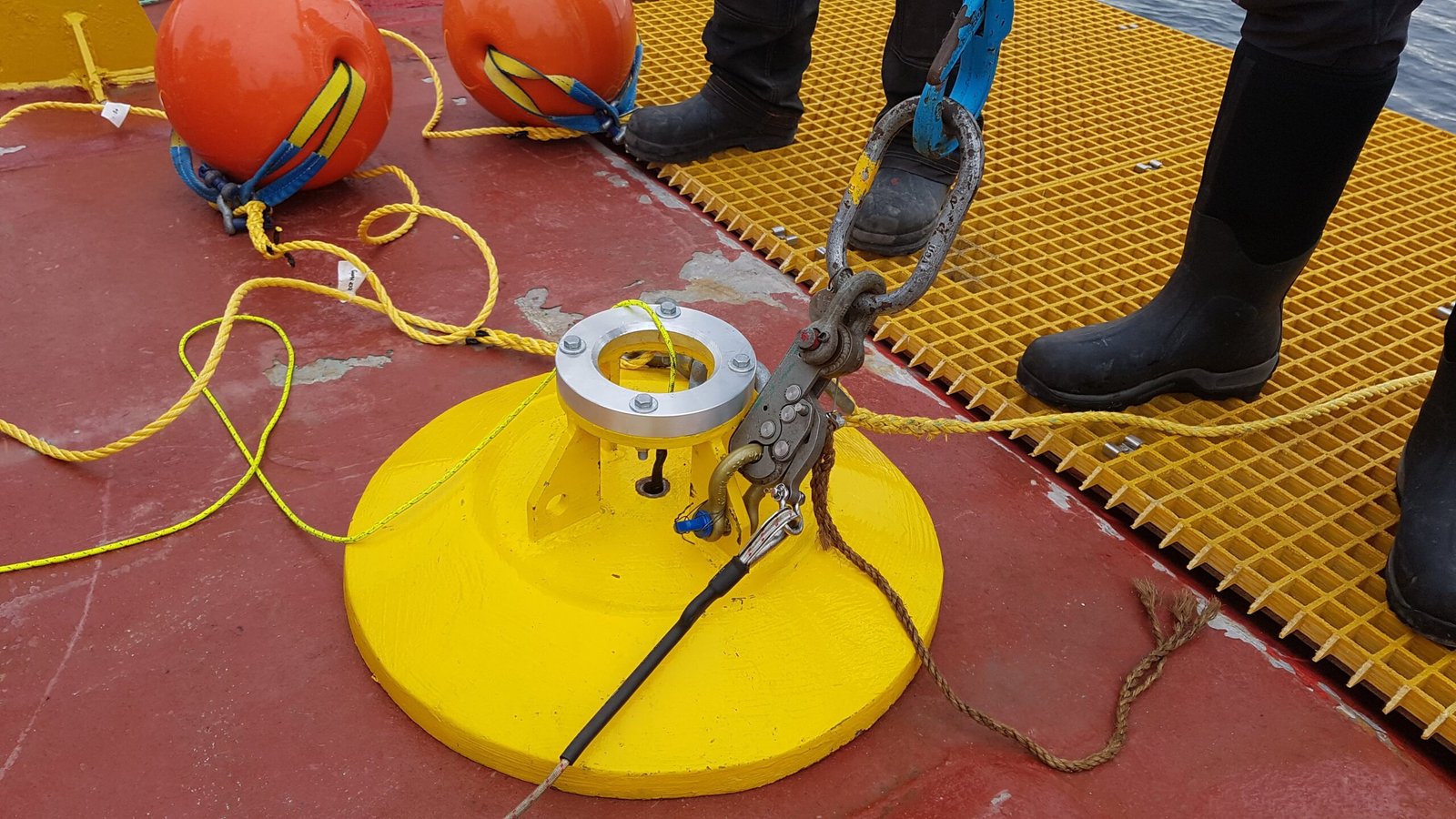

Buoy and 'Aids to Navigation' management

Underwater arches and Subsea buoyancy

Lifeboat and Fast Rescue Craft handling and recovery

Subsea asset deployment and retrieval

Launch and Recovery Made Simple

SEA-Lift™ provides redeployable, high-load connections that are easy to use. It’s specifically designed for harsh environments, allowing for simple and reliable connection and disconnection.

Product Highlights:

- Up to 100te Safe Working Load (SWL/WLL)

- Fully redundant secondary locking including options for remote release

- Lifting package integration with lead-in cone

- Cost-effective design reduces capital cost

- Self-centers during deployment with wide approach angles, reducing installation costs

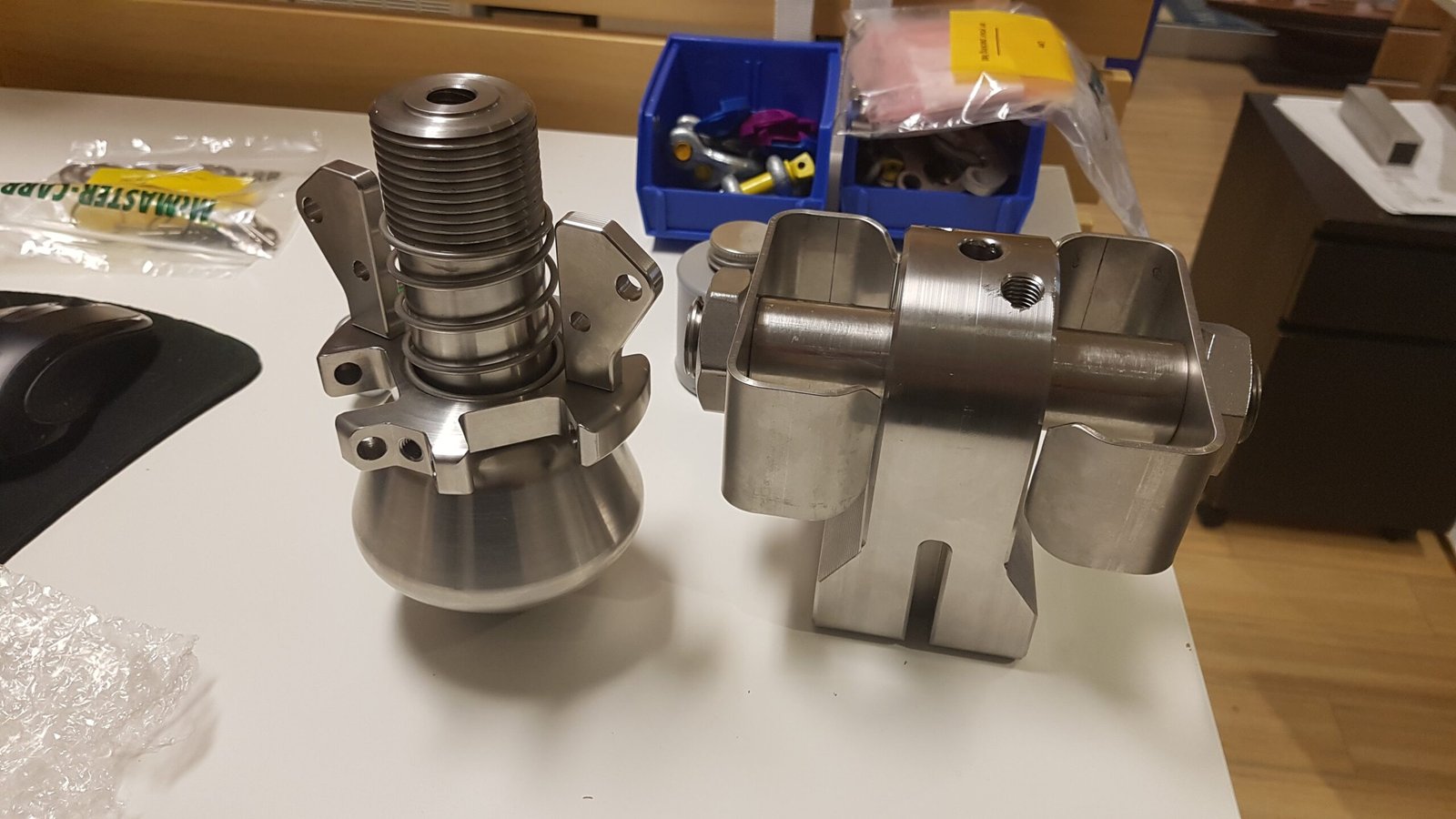

- Only 5 Moving parts, with no dissimilar materials, reducing corrosion risk

- Configurable coupling reduces need for additional components during hook-up

Design Quality & Certifications:

- Material options: 316SS, 17-4SS or Gr5 Ti

- Design approval in principle by ABS

- Specific project approvals by Lloyds

- Mil-STD proof-load prior to shipping

- Canadian designed, assembled and tested

- In-house manufacturing upon request

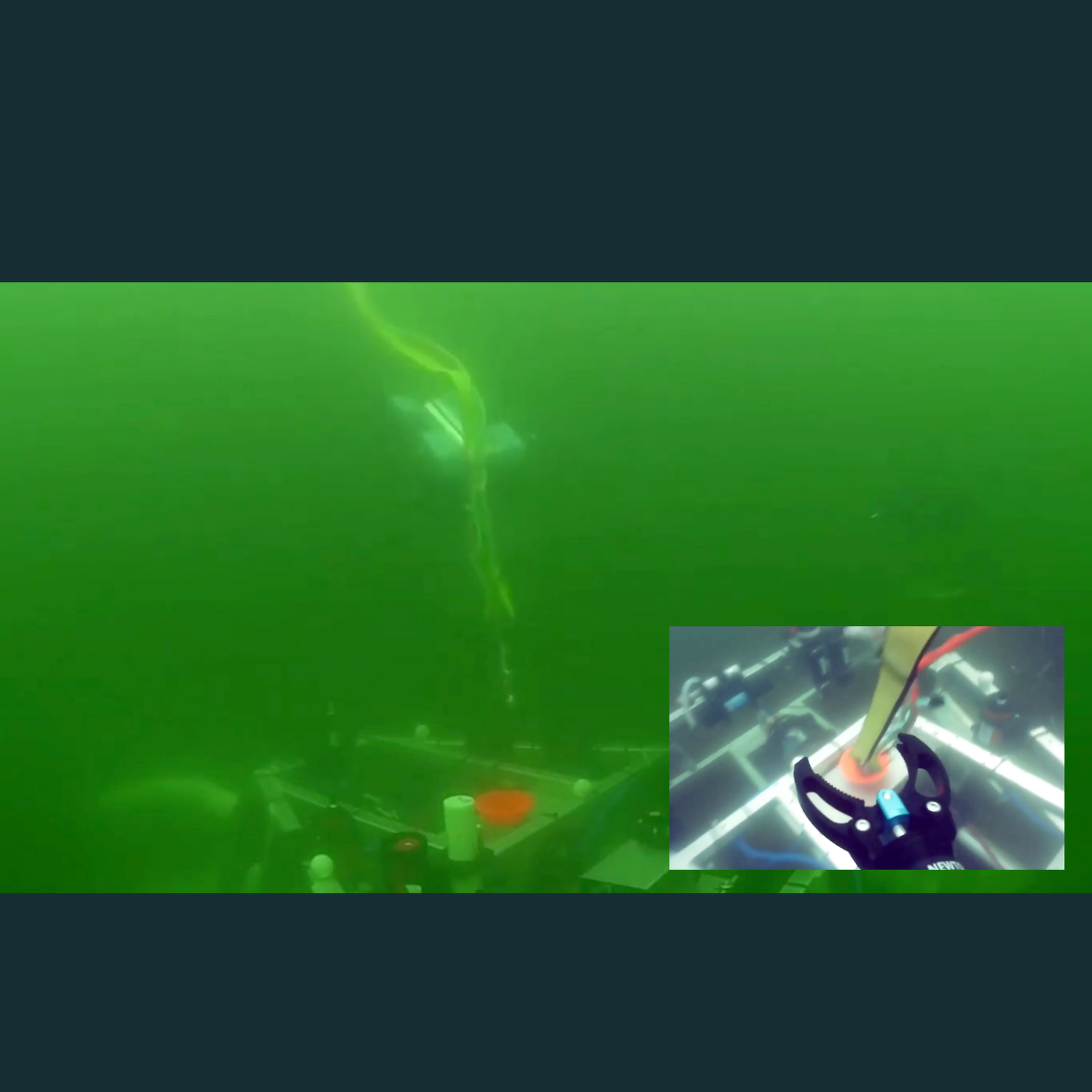

SEA-Lift™ in Action

Frequently Asked Questions

What is the safety factor for the assembly?

The working load limit (WLL) is stamped on each assembly, with a safety factor of 4:1. This means the material will not yield until at least four times the WLL has been applied to the connector.

Can the connector release under load?

In its standard configuration and by design, the SEA-Lift™ connector cannot release under load. All load must be fully removed before the connector can be released. This ensures secure and reliable operation under all conditions.

Are the connectors proof loaded?

All SEA-Lift™ units are proof-loaded to 125% of their WLL rating before leaving the factory. Load test certificates are available for an additional fee.

Is there a secondary means of locking the assembly closed?

All SEA-Lift™ units include locking screws that allow the user to lock the assembly closed for long-term connection. Larger connectors may have more complex secondary locking mechanisms; please contact us for details.

What maintenance is required?

If used in seawater, the SEA-Lift™ should be rinsed with freshwater. A greasing procedure is also provided with larger units.